From Data to Insight: MBTS Modeling Solutions

MBTS goes beyond delivering precise testing data — we provide the final step in transforming that data into real engineering value. Our modeling solutions support multiple stages of battery pack development, from early concept to final prototype. For concept and system engineers, we offer 1D simulation models that support the initial study of cell integration and A-sample development. For advanced stages, we enable FEM-based simulations that accurately model breathing and swelling effects, supporting B-sample refinement and the finalization of functional prototypes. With MBTS, your testing data becomes a powerful asset for design and development.

Simulation Model

Lumped Parameters Multiphysics

Finite Elements Method Model

Tests Design and Calibration

Custom Software Support

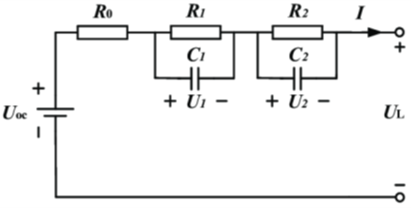

Lumped Parameters Multiphysics Model

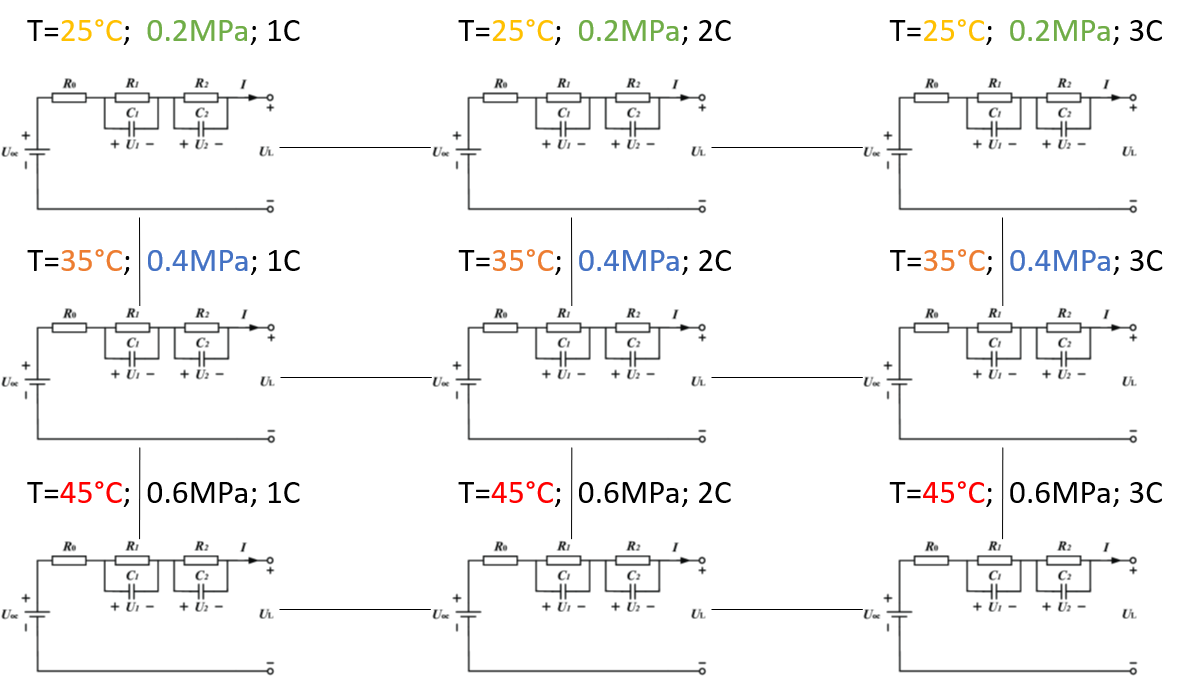

The proprietary system developed by MBTS enables advanced testing and modeling capabilities by providing independent control over thermal and mechanical boundary conditions. This allows for the inclusion of additional physical parameters—such as temperature and pressure—during testing, thereby expanding the parameter space available for the calibration of equivalent circuit models. As a result, the accuracy and predictive power of the simulation models are significantly enhanced.

Electrical Protocol

The electrical protocol used for calibrating the equivalent circuit model remains unchanged from the standard procedure. However, it can now be executed under precisely controlled mechanical and thermal conditions, and across a range of predefined states, enabling more comprehensive and representative model calibration.

As a result, a matrix of calibrated equivalent circuit models (ECMs) is generated, each corresponding to a specific combination of pressure and temperature conditions. By interpolating across this matrix, it becomes possible to estimate model behavior at intermediate thermal and mechanical states, enabling continuous and accurate simulation across a wide operating range.

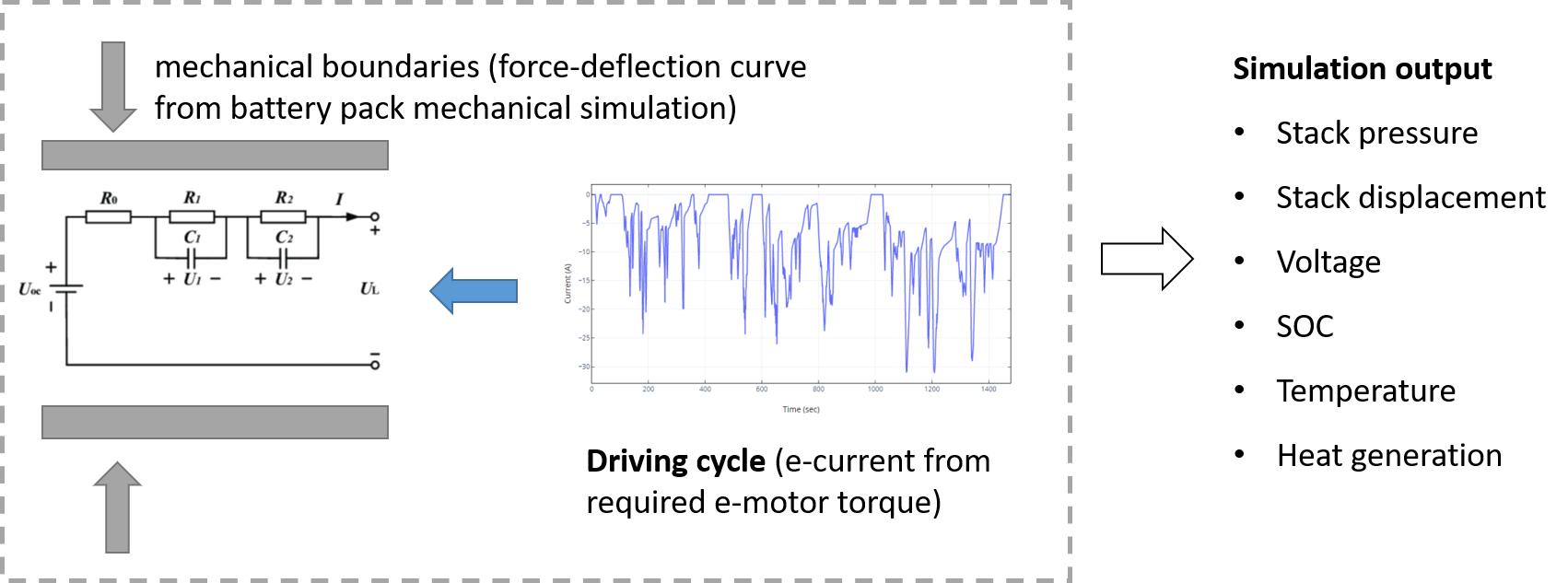

A Robust and Reliable Digital Twin Model for Battery Systems

The outcome of the multiphysics equivalent circuit model (ECM) is a fully empirically calibrated digital twin of the battery system. This approach eliminates the need for semi-empirical analytical models, which typically require manual tuning of numerous parameters. The integrated testing platform developed by MBTS enables comprehensive empirical characterization across mechanical, thermal, and electrical domains, significantly enhancing the fidelity and applicability of data-driven battery models.

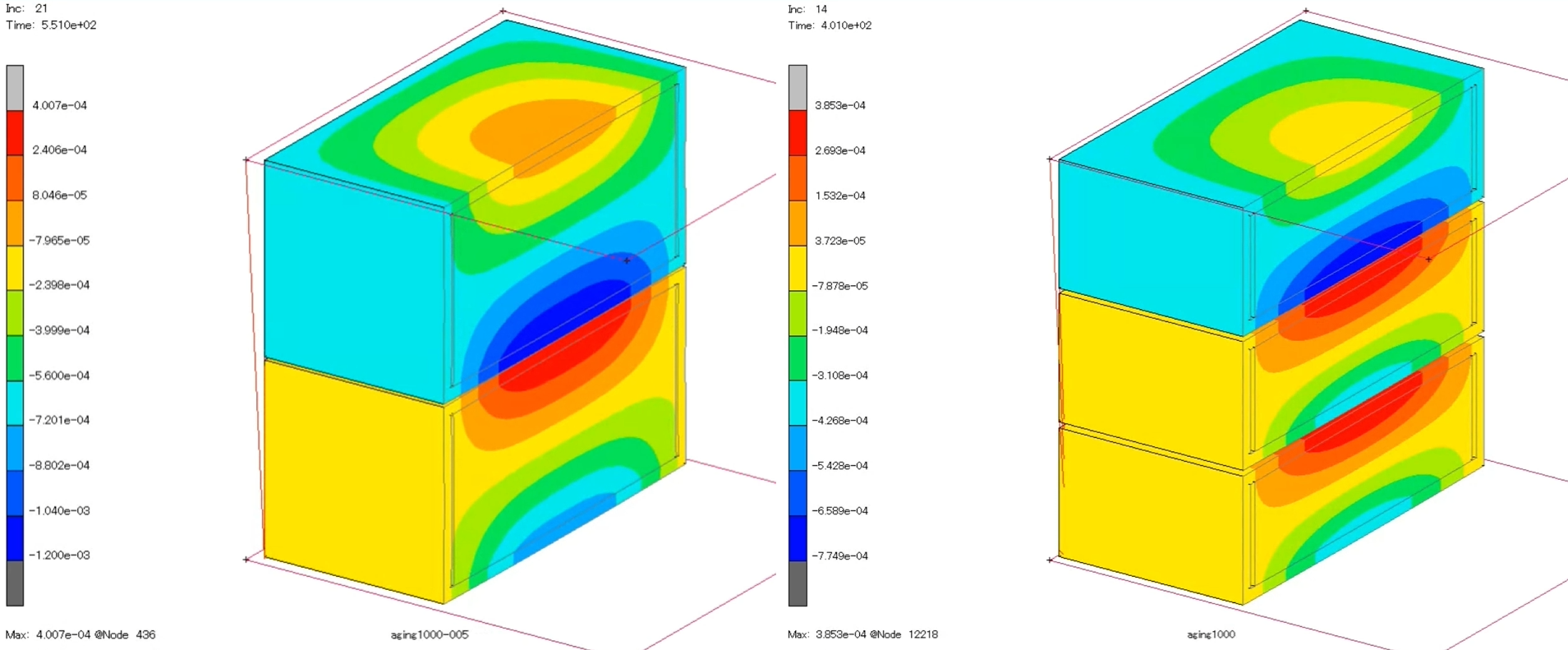

FEM Model for Swelling and Breathing analysis

The calibration of a finite element method (FEM) model for analyzing cell breathing and swelling involves a complex workflow, including experimental cell testing, material characterization, and a rigorous validation process. MBTS offers a turnkey solution that spans the entire workflow—from single-cell mechanical testing to full integration into a mechanical FEM simulation. By modeling pressure distribution within the cell stack, the simulation can identify potential structural failures in the cell constraint frame, enabling proactive design optimization.

complete workflow from testing to simulation

MBTS delivers a comprehensive end-to-end workflow, encompassing initial test design, material data generation, and model calibration within FEM software environments.

data validation

The implementation of a standardized workflow establishes the foundation for efficient material validation, significantly reducing both development time and associated costs.