Power Your Battery Innovation with Precision and Expertise

At MBTS, we understand that high quality testing data is the foundation of successful battery pack development. That’s why we combine cutting-edge testbench technology with over a decade of hands-on industry experience. Our skilled engineers and expert test designers ensure every data point meets the highers standards, because performance stars with precision.

Breathing and Swelling Analysis

Electrochemical Impedance Spectroscopy

Material Card Generation

Hysteresis Analysis

C-rate Analysis

HPPC Analysis

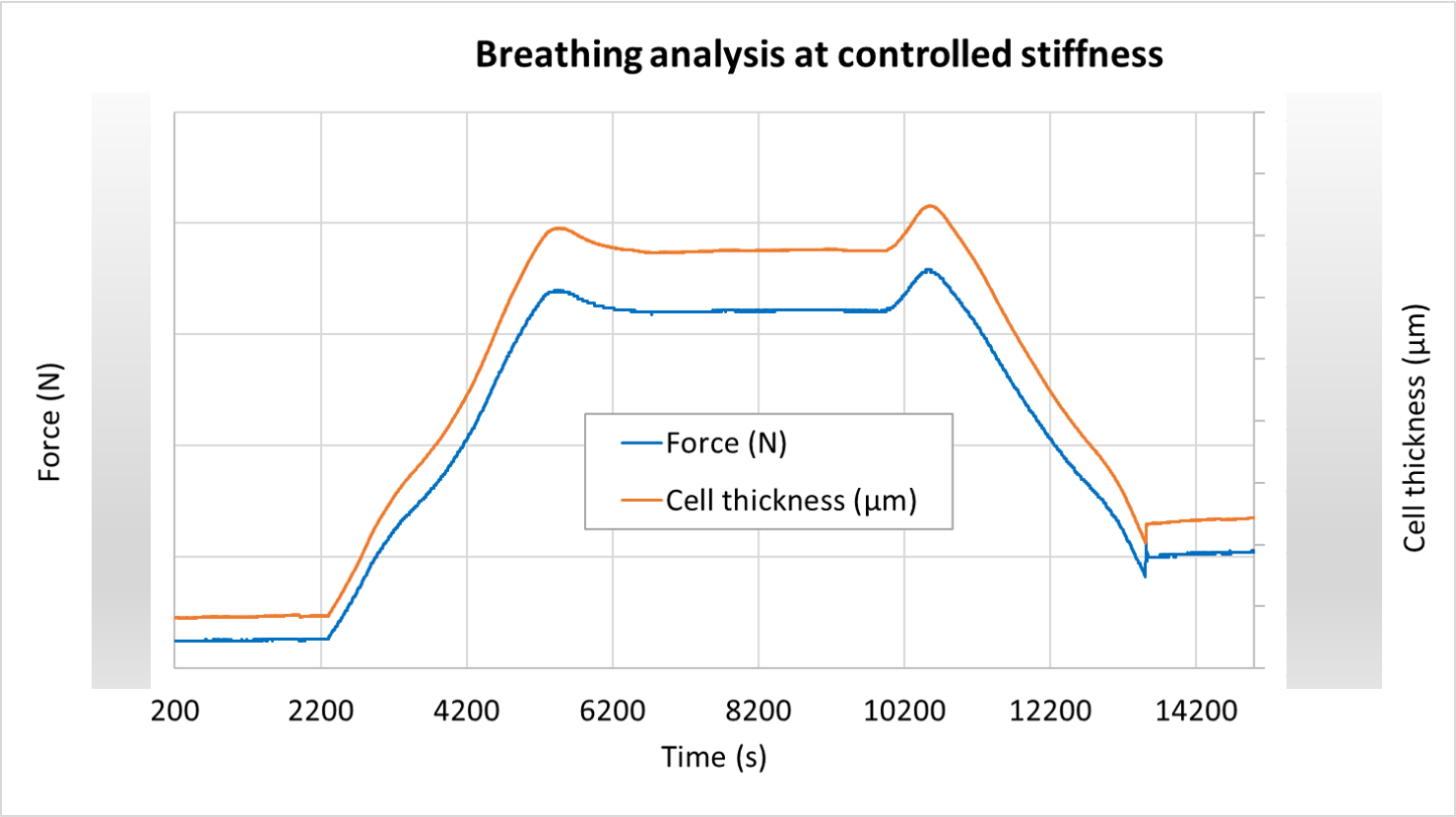

Breathing and Swelling Analysis

Whether using cell-to-module or cell-to-pack configurations, prismatic and pouch cells must be carefully stacked within the battery pack. As these cells naturally expand and contract throughout their lifecycle, internal stack pressure fluctuates—posing risks such as mechanical failure, reduced performance, and accelerated aging. Our advanced analysis of cell breathing and swelling behavior empowers precise design of battery pack frames and compression systems. The result? Minimized design iterations, lower development costs, and enhanced long-term performance.

temperature control and monitor at any condition

Our patented system guarantees the complete control and precise monitoring of the cell temperature even at high C-rate conditions

force and displacement measurement

Precise monitoring of the force and displacement with outstanding displacement accuracy up to 0.5 μm.

3 types of mechanical control

Three control modes: force control, displacement control, and stiffness control. This enables comprehensive testing under realistic operating scenarios.

synchronized data

Mechanical, electrical, and thermal parameters are simultaneously acquired using a single datalogger. This unified acquisition ensures time-synchronized, eliminating the need for extensive post-processing and data alignment.

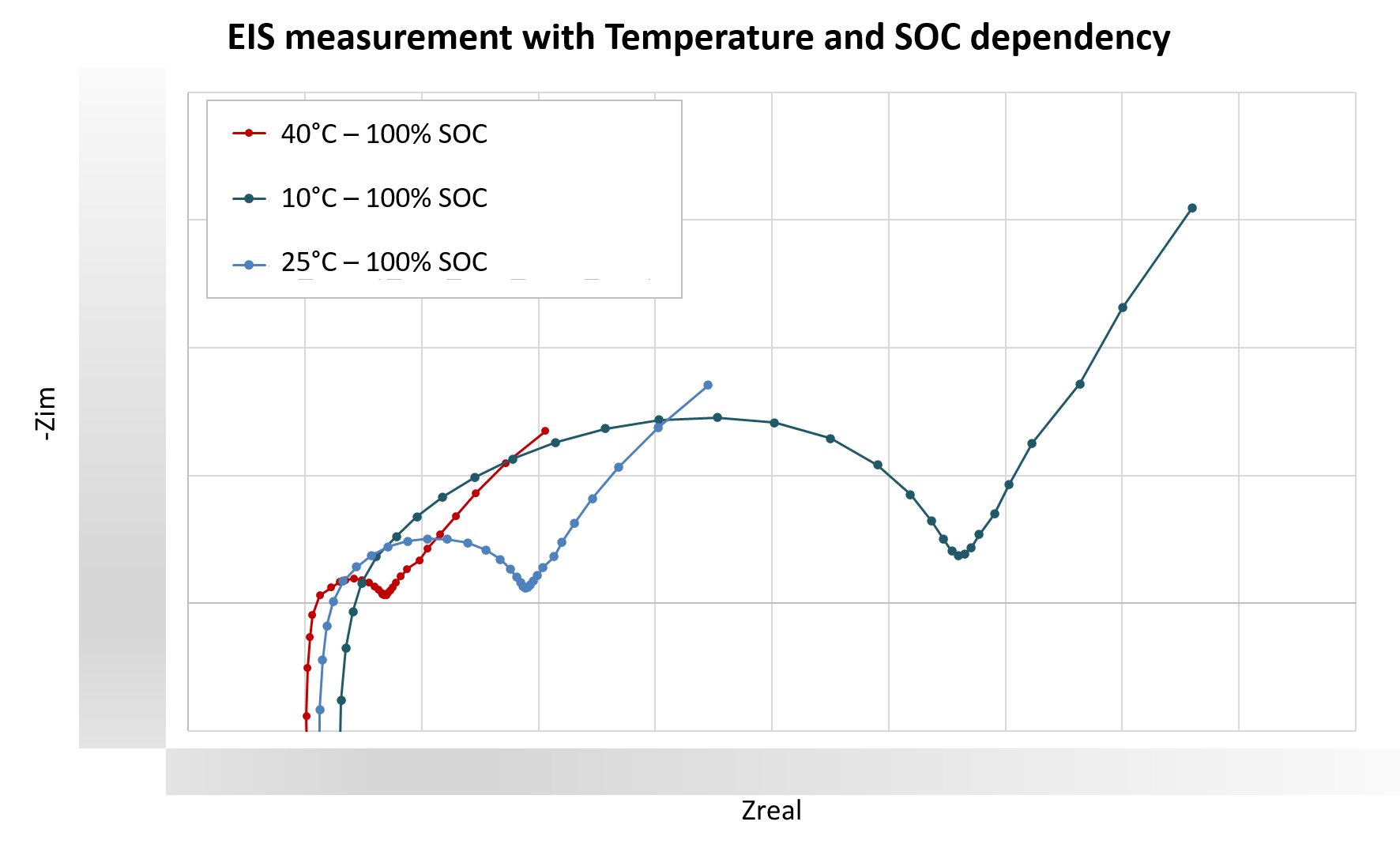

Electrochemical Impedance Spectroscopy

Electrochemical Impedance Spectroscopy (EIS) can be applied in the early stages of cell development to characterize internal impedance under varying temperature and pressure conditions. This analysis supports the optimization of cell performance and assists in the selection of the most suitable internal materials.

automated

The system is fully automated, enabling impedance analysis across a range of pressures and temperatures, minimizing testing time and ensuring repeatable measurements.

fast thermal conditioning

Our patented system utilizes Peltier elements with a peak thermal power of 3.6 kW to actively control the cell’s surface temperature. This enables rapid transitions between temperature setpoints.

Wide range of applicable conditions

Pressure and temperature can be applied independently, enabling decoupled control of each parameter. This allows for isolated analysis of their individual effects on cell impedance.

high customization level

The testbench construction allows for highly customizable test protocols. Our experts can provide support on the definition of the protocols that best suits for you.

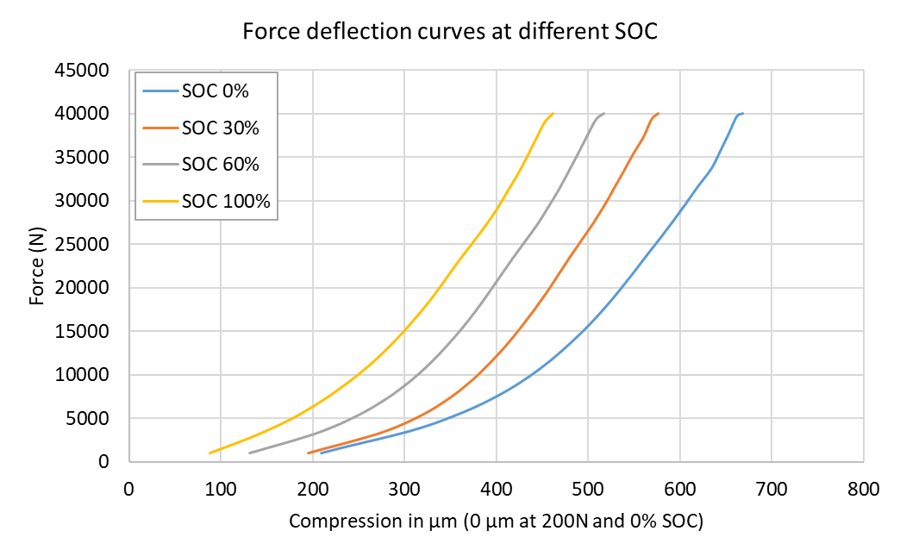

Material Card Generation

The measured force-deflection curve enables the generation of a mechanical material card for the cell. Since mechanical properties are influenced by state of charge (SoC), temperature, and aging, our testbench is designed to systematically investigate the impact of each of these factors. This allows for accurate modeling of the cell’s mechanical behavior under varying operational conditions.

fast data generation

Get the data to build your cell simulation model with about 1 week of testing.

expanded test matrix

Include State of Charge, temperature and ageing status as parameters of your model.

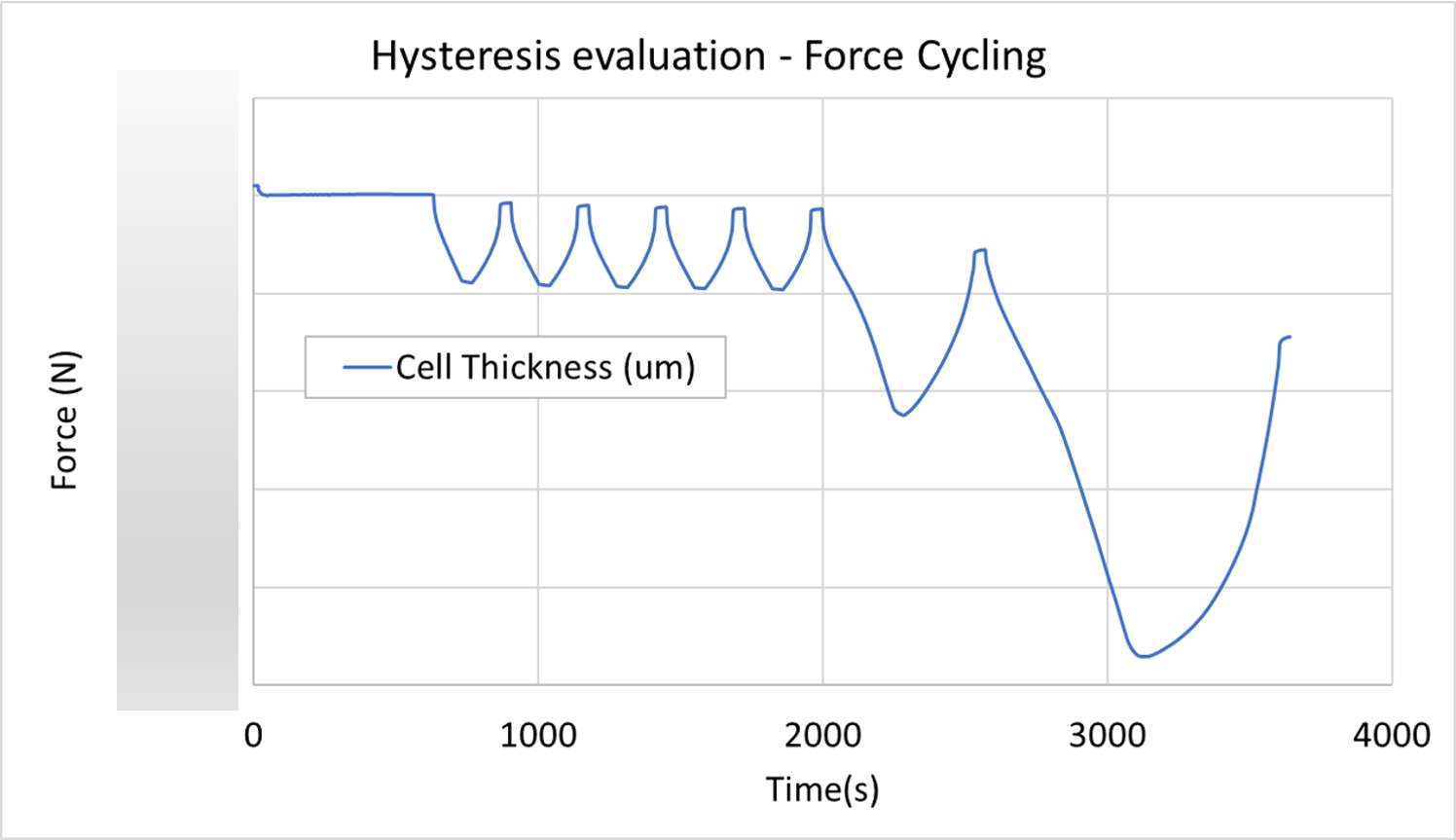

Hysteresis Analysis (Mechanical)

Hysteresis analysis is critical for defining the optimal mounting and assembly procedures of the cell stack within the battery pack frame. During compression, residual deformation can occur, resulting in a loss of effective stack pressure post-assembly. Insufficient compression may lead to a range of issues during production and validation—such as failure in vibration testing—compromising the mechanical design.

high accuracy in displacement measurement

Residual compression of the cell resulting from force cycling can reach magnitudes of several tens of micrometers. Our system is capable of detecting these subtle variations with high precision, ensuring accurate and reliable measurement of mechanical deformation throughout the test cycle.

better understanding of the cell mechanical behavior

Specialized tests, such as hysteresis analysis, can help identify and mitigate potential issues throughout the battery pack development process and during production. This analysis can be conducted with consideration of temperature dependencies to ensure accurate characterization under varying thermal conditions.

C-rate Analysis

External compression and temperature significantly influence cell performance. Generally, increased pressure can lead to performance degradation, while elevated temperatures tend to enhance performance at the cost of accelerated aging. However, a minimum compression is essential to prevent electrode delamination and to achieve optimal electrochemical behavior. Conducting a pressure sensitivity study allows identification of the optimal operating pressure for the cell stack. When combined with breathing and swelling analysis, this approach provides critical insights for the optimum design of the battery pack structure.

temperature control and monitor at any condition

Our patented system guarantees the complete control and precise monitoring of the cell temperature even at high C-rate conditions

force and displacement measurement

Precise monitoring of the force and displacement with outstanding displacement accuracy up to 0.5 μm.

3 mechanical control types

Three control modes: force control, displacement control, and stiffness control. This enables comprehensive testing under realistic operating scenarios.

synchronized data

Mechanical, electrical, and thermal parameters are simultaneously acquired using a single datalogger. This unified acquisition ensures time-synchronized, eliminating the need for extensive post-processing and data alignment.

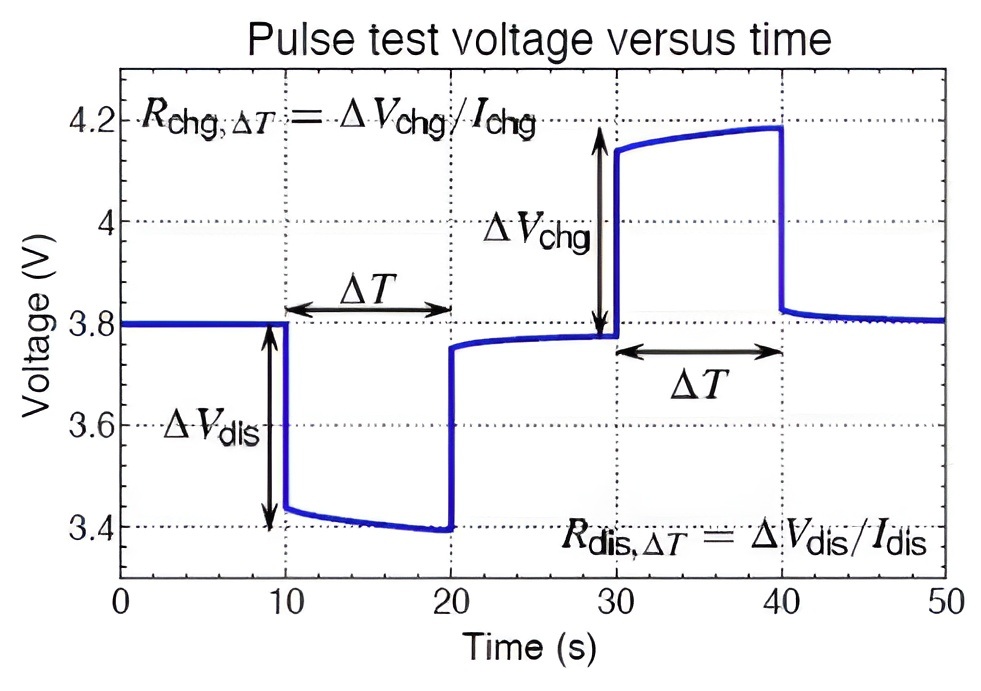

Hybrid Pulse Power Characterization Analysis

The Hybrid Pulse Power Characterization (HPPC) test is commonly used to evaluate a cell’s internal impedance under varying C-rates and states of charge (SoC). With the MBTS system, this analysis can be further enhanced by incorporating temperature and pressure as additional parameters. This enables a more precise and comprehensive characterization of the cell’s internal impedance, significantly improving the fidelity of simulation models and supporting more accurate performance predictions under real-world conditions.

temperature control and monitor at any condition

Our patented system guarantees the complete control and precise monitoring of the cell temperature even at high C-rate conditions. Furthermore, with temperature control on the cell’s surface, temperature transition is faster, reducing the test time.

force control

Internal impedance can be evaluated under controlled pressure conditions, providing more comprehensive test data for calibrating high-fidelity simulation models. Explore our digital solutions to discover how this data supports the next steps in advanced model development.